More glass – fewer walls. Can the hardware withstand the architectural trend?

Modern architecture is confidently moving towards transparency. Large glazed areas today are not only an aesthetic element but also a tool for energy efficiency, comfort, and even increasing the value of real estate.

- Architectural logic chooses large windows

- What is considered a large window?

- More light – less light: light transmission and selective glass

- Challenges of large-format windows

- Heavier glass units – what it means for hardware

- Global experience of panoramic glazing: commercial buildings vs residential sector

- The trend for large windows and transparent façades is here to stay

- Hardware ready for large formats

Architectural logic chooses large windows

The increase in window area is a consequence of the desire for natural light, visual expansion of space, and harmonious blending of the interior with the landscape. Incorporating the view outside the window into the overall feeling of comfort is becoming increasingly popular in the design of both single-family and multi-apartment buildings.

Technological progress in insulated glass units, profile systems, and hardware makes it possible to create façades with large glazed areas without compromising the building’s energy balance.

What is considered a large window?

If a 1.5 × 1.5 m window is a standard size, then glazing from floor to ceiling that spans the entire width of a room is considered large.

In private houses and apartments, windows with a height or width exceeding 2.2–2.4 m can be regarded as large.

- ● Large – constructions from 2.4 m high or more than 2 m wide.

- ● Panoramic – from floor to ceiling (2.5–3.0 m) or with an area over 5–6 m2.

In public buildings, these dimensions are usually even greater.

More light – less light: light transmission and selective glass

It is worth noting that doubling the window opening in practice does not always mean doubling the level of natural illumination. Large windows should not cause overheating of interiors in summer.

That is why selective glass is used – it reduces the amount of solar energy entering the room. At the same time, the visible light transmission decreases, and architects sometimes have to increase the glazed area to compensate for this reduction in brightness.

Challenges of large-format windows

Large windows mean greater loads. To ensure strength, stability, and safety of the structure, manufacturers use insulated glass units with thicker glass – 6, 8, or even 10 mm. This reduces deformation from wind pressure and improves acoustic comfort. As a result, the insulating glass unit becomes a complex engineering product that simultaneously transmits light, retains heat, and protects against overheating.

At the same time, the weight increases. If in a double-glazed unit the glass thickness is increased from 4 mm to 6 mm, the product’s weight rises by about 50% – from 30 to 45 kg/m2.

Heavier glass units – what it means for hardware

Increasing the size of sashes leads to a rise in their weight not only because of the larger glass area but also due to the thicker glass required for such big windows. Under these conditions, the hardware bears special responsibility for the correct and reliable operation of the window.

In addition, increased requirements for sound insulation or burglary resistance typically add another 20–50% to the sash weight.

If standard hardware on the market – usually designed for loads up to 100 kg – continues to be used for much heavier sashes, operational problems may arise: sagging of the sash, poor sealing, possible glass cracking, and other issues.

Global experience of panoramic glazing: commercial buildings vs residential sector

Glass walls have long been used in commercial buildings, dating back to the previous century. One of the earliest examples of fully glazed façades – the Equitable Building in New York – was completed in 1915. Today, multi-storey office centres with glass façades are a common sight around the world.

However, in mass-market multi-apartment construction or one- and two-family houses of the middle class in the USA and Germany, this trend is developing more slowly than in Ukraine. Fully glazed houses in the USA generally belong to the premium property segment. In Ukraine, by contrast, recent years have shown a clear trend in new developments – even in relatively affordable housing – towards larger windows and fully glazed loggias.

Less bureaucratic pressure and lower construction costs in Ukraine provide developers with more opportunities to attract buyers through modern design.

The trend for large windows and transparent façades is here to stay

The trend for large windows is not a passing fashion but the result of technological progress. Transparent façades are shaping the architecture of the 21st century, where natural light, aesthetics, and energy efficiency are fundamental values.

For reliable performance of large window structures, the coordinated interaction of all components – glass, profile, and hardware – is crucial.

Hardware ready for large formats

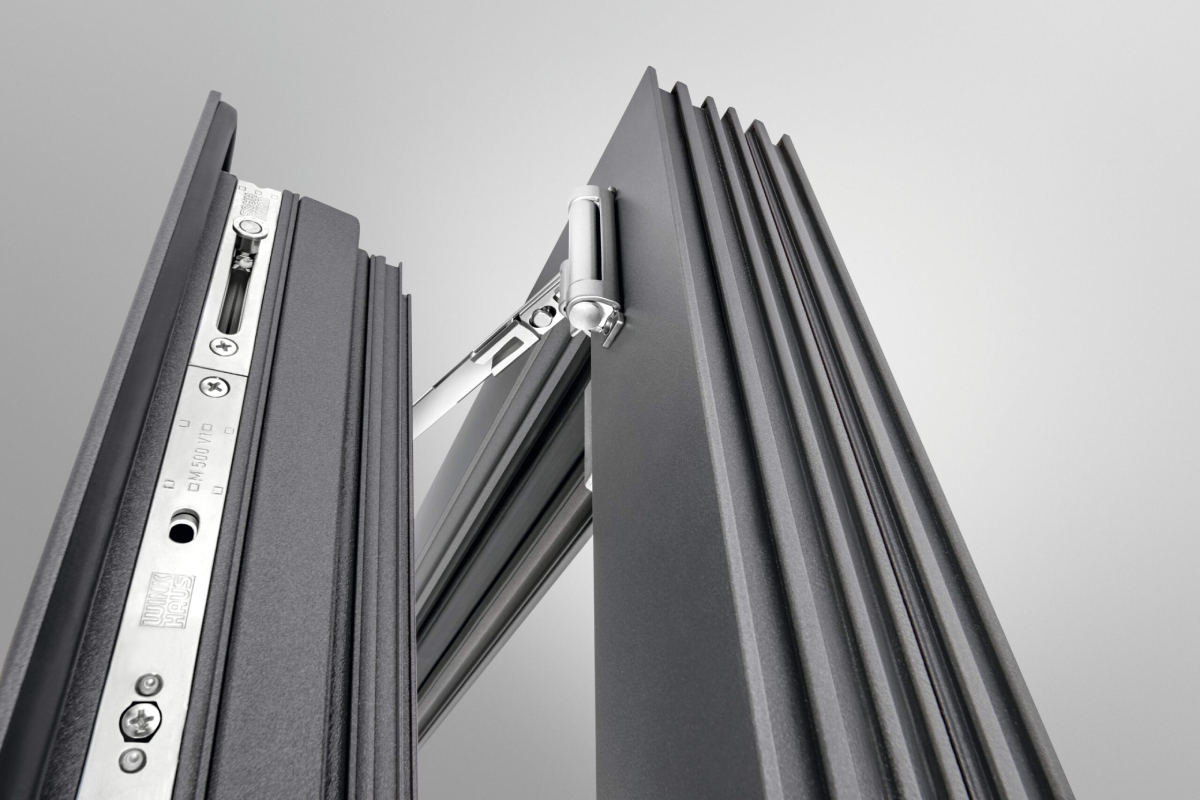

Modern architectural trends set new requirements for the reliability of window hardware. As sash areas grow and glass unit weights reach dozens of kilograms, hardware becomes the key element ensuring stability, safety, and durability of the structure.

The updated Winkhaus activPilot hardware in its standard configuration is designed for sash loads up to 150 kg, whereas typical products on the market are usually rated for a maximum load of 100 kg. This significant difference opens new possibilities for architects and window manufacturers. It now becomes easier to realise modern projects with large glazing formats without having to switch to special reinforced configurations.

For even heavier sashes weighing up to 200 kg, the reinforced Winkhaus activPilot Giant hardware is available, further expanding the opportunities for architects and manufacturers.

The increased load-bearing capacity of the hardware supports the “more glass – fewer walls” trend and allows the creation of panoramic windows that are as reliable as conventional designs. For users, this means effortless opening and tight sealing even of heavy sashes; for manufacturers, it means confidence in the long-term durability of windows that meet the demands of modern architecture.