New trends — reinforced challenges: the new generation of Winkhaus hardware for 150 kg sashes

Modern architecture is increasingly leaning towards expanding the area of transparent structures. Large windows visually enlarge the space, fill it with natural light, and give façades a contemporary appearance.

However, this trend also brings a technical challenge: larger glazed surfaces mean heavier sashes and, consequently, higher demands for hardware strength and reliability. Manufacturers of window systems must offer solutions capable of withstanding extreme loads and meeting not only safety standards but also customer expectations.

One of the key indicators of additional quality in this field has become the European testing certificate TBDK, developed by the German organisation Gütegemeinschaft Schlösser und Beschläge e.V., which is part of the RAL-Gütezeichen system.

- What the TBDK test is

- The importance of TBDK for the market

- New Winkhaus hinges for heavy sashes with TBDK certification

- Perfection in every detail

- Conclusion

What the TBDK test is

This is a standard testing method that examines doors, fittings and window systems for resistance to burglary, pressure, or mechanical stress.

Within the TBDK test, the system (door or window) is subjected to:

- ● static loads (pressure, attempts to bend or pull apart);

- ● dynamic impacts (simulating blows or heavy-object strikes);

- ● break-in attempts using a standard set of tools.

TBDK defines the requirements for fixing load-bearing components of turn and tilt-and-turn hardware. Products that successfully pass the testing confirm increased reliability compared to minimum requirements and gain a strong argument for market positioning.

Often, the TBDK certificate appears in tender documentation as a mandatory criterion for participation in large-scale projects—from commercial buildings to residential complexes.

The uniqueness of the TBDK directive lies in its clear division of responsibility:

- ● the hardware manufacturer is responsible for the strength of its components;

- ● the window manufacturer is responsible for the correct installation of the hardware in the profiles and compliance with the standard’s requirements.

The importance of TBDK for the market

- Quality and reliability assurance

- ● A product that has passed the TBDK test confirms its compliance with the requirements for mechanical strength, airtightness and functionality.

- Competitive advantage

- ● Participants in construction tenders in Germany and the EU often require certified systems.

- ● Having a TBDK certificate simplifies access to government projects and large developments.

- Compliance with building regulations

- ● TBDK is closely linked to the RAL-Gütezeichen (RAL Quality Mark) system.

- ● This helps manufacturers avoid issues with building supervision and inspections, as the products officially confirm their quality.

- Protection against claims

- ● If a window or door has a TBDK certificate, it is easier for the manufacturer to prove compliance with standards.

- ● This reduces the risk of complaints from buyers or developers.

- Marketing effect

- For the end consumer, the TBDK mark equals trust.

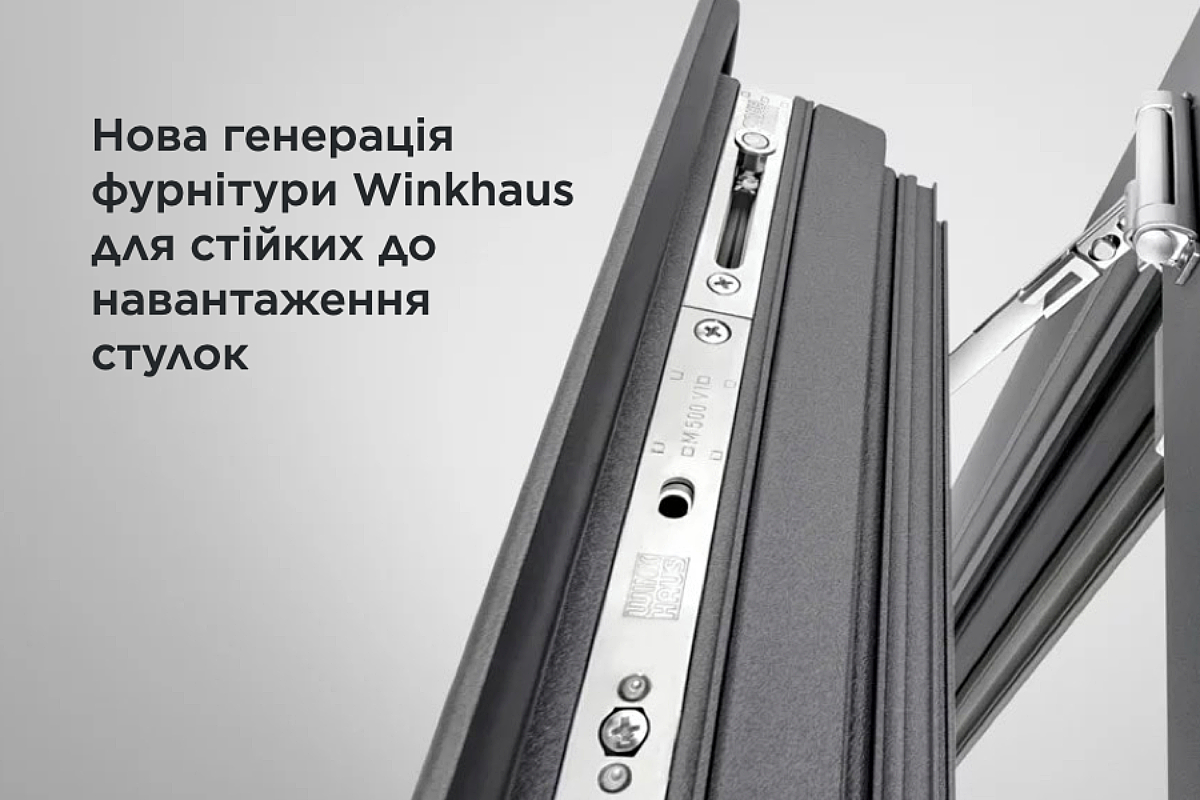

New Winkhaus hinges for heavy sashes with TBDK certification

Winkhaus has introduced a new range of hinges designed for sash weights up to 150 kg. This opens up new opportunities for architects and developers to create large-scale transparent structures while maintaining safety and reliability.

The new series (130/150 kg) complies with TBDK requirements and the European standard DIN 13126-8:2017. Key features include:

- ● enlarged support area for transferring loads to the frame;

- ● extended load-bearing pins for even weight distribution;

- ● reduced sash support pin height by 5 mm for easier installation;

- ● specially shaped upper pin profile for simplified hanging;

- ● increased reliability for burglar-resistant windows.

Perfection in every detail

Every new Winkhaus solution is the perfection of previous designs, refined through years of research and experience. In the new design, the upper frame hinge is made of steel, and the pin is insulated with polymer inserts. This eliminates metal-to-metal contact and, consequently, the risk of corrosion. The result is long-lasting performance without the need for additional maintenance.

Tests have confirmed reliability:

- ● TBDK pull-out test — 4200 N (428 kg of force);

- ● no broken screws;

- ● no cracks in the hardware or profile;

- ● after loading, the hinge protruded no more than 2 mm.

Conclusion

The increase in glazing area in modern architecture inevitably raises hardware requirements. TBDK is becoming an essential trust indicator for architects, developers and end customers. Innovative Winkhaus solutions, certified under this standard, confidently combine design, safety and durability in the transparent structures of the future.