Windows: explosion-proof

According to the United Nations1, approximately 80% of injuries and deaths among the civilian population in cases of explosions during acts of terrorism or bombings are caused by primary and secondary fragments. Secondary fragments are formed as a result of the destruction of building structures, road surfaces, and so on. Furthermore, 80% of injuries from fragments and debris are due to injuries from shattered glass. In other words, around 64% (80%*80%) of all deaths and injuries resulting from an explosion are inflicted by shattered window glass. Glass in windows and façade glazing is the weakest element of a building in terms of resistance to the shock wave. Fragments of ordinary "raw" glass have sharp edges and disperse at high speed, posing a danger to people.

- Can the consequences of explosions be influenced?

- Prehistory. Searching for the availability of explosion-resistant windows in Ukraine

- The general history of studying the consequences of explosions for buildings

- Explosion resistance standards for windows

- Windows, Doors, and Blinds. Explosion Resistance. Classification and Technical Requirements. Part 2. Test Range. (EN 13123-2:2004, IDT) DSTU EN 13123-2:2006

- What has been done in Ukraine regarding the testing of windows for blast resistance?

- Step 1. The first explosion

- Step 2. The bar has been raised

- Step 3. Second class of explosion resistance

Can the consequences of explosions be influenced?

If more than half of the injuries and deaths occur not from the explosion itself or from the shrapnel of the projectile, but due to shattered glass caused by the explosion, is it possible to change the statistics, for example, in particularly vulnerable places such as kindergartens, schools, and hospitals?

The question was raised by Ivan Bohdan, a volunteer and CEO of WINKHAUS Ukraine, and Mykhailo Orlenko, the director of Vіkna-Star, TM company..

Prehistory. Searching for the availability of explosion-resistant windows in Ukraine

In recent years, Winkhaus Ukraine, OKNA.ua, and several other window market companies have widely popularized the use of burglar-resistant windows2. In Ukraine, licensed companies3 have emerged that produce certified burglar-resistant windows of RC2 class.

Observations of damage after the aggressor's shelling provided a clue to finding the specifications for blast-resistant window components. The break-resistant windows, meeting the RC2 protection level, appeared significantly better after the shelling compared to regular ones. This prompted a thorough investigation into whether it is possible to enhance RC2-based windows to make them safe during explosions.

The general history of studying the consequences of explosions for buildings

In general, research on the consequences of explosions for buildings intensified after the Second World War. In the latter half of the 20th century, numerous studies were conducted on the characteristics of explosions and the interaction of shock waves with buildings and structures4, 5, 6, 7. A series of experiments were conducted, and empirical and semi-empirical methods for calculating the parameters of shock waves were developed.

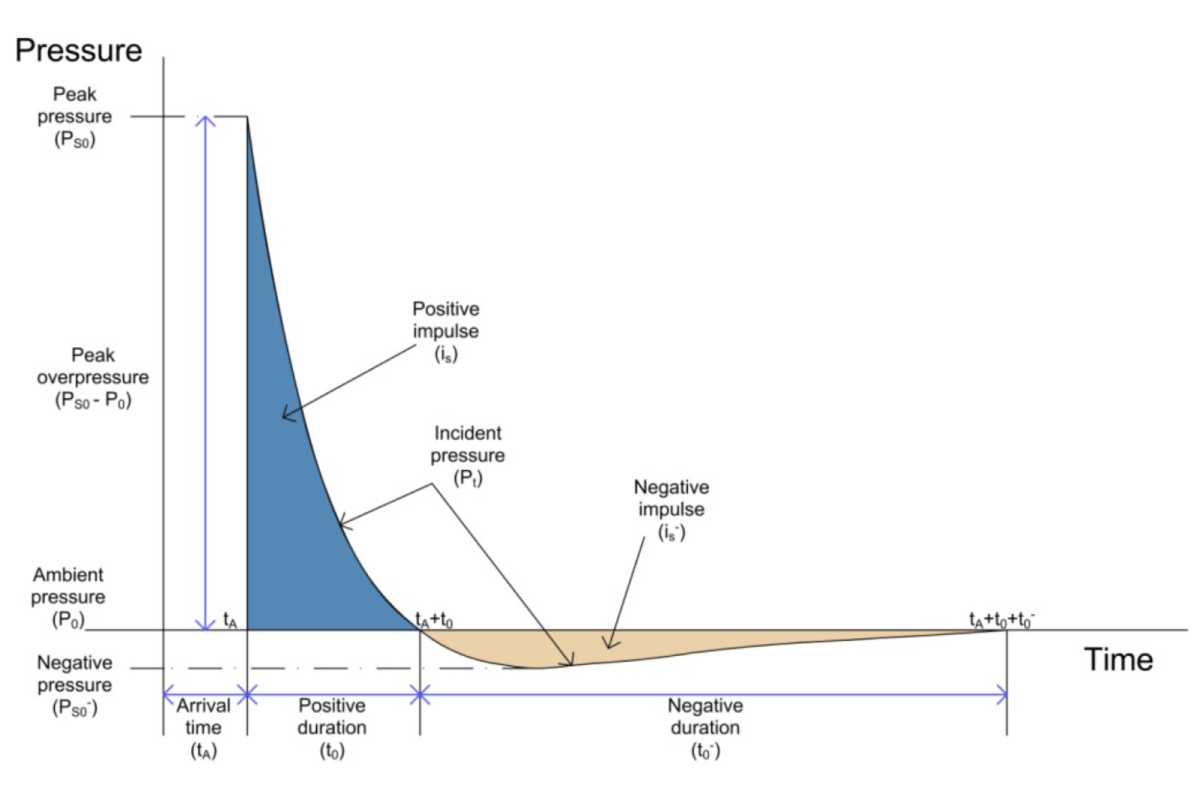

The shockwave is the cause of the formation of glass fragments moving at high speeds. An ideal shockwave looks like the one shown in Figure 1. A sharp spike in air pressure leads to destruction and depends on the duration of the positive pressure action. Afterward, a negative pressure arises in the wave, but its peak is insignificant compared to the main peak.

To calculate the impact of an explosion on buildings and structures, two main parameters of the shock wave are primarily needed – the peak overpressure (Pso - Po) and the duration of the positive phase (to).

Numerical calculation methods become important when predicting threats, including in dense urban development and when considering complex building shapes.

Explosion resistance standards for windows

It should be noted that blast-resistant, break-resistant, and bullet-resistant windows are different types of windows. These properties are not identical.

The first standards for window explosion resistance in the world began to appear in the early 2000s. The most commonly used standards8:

- ● EN 13123-1,2 Windows, doors and shutters - Explosion resistance.

- ● GSA-TS01-2003 (General Services Administration / Standard Test Method for Glazing and Window Systems Subject to Dynamic Overpressure Loadings, 2003).

- ● ISO 16933:2007 (International Organization for Standardization / Glass in Building – Explosionresistant security glazing - Test and classification for arena air-blast loading, 2007).

- ● PDC-TR 10-02 (US Army Corps of Engineers, Protective Design Center / Blast Resistant Design Methodology for Window Systems Designed Statically and Dynamically, 2012).

- ● ASTM F1642-17 (American Society for Testing and Materials / Standard Test Method For Glazing And Glazing Systems Subject To Airblast Loadings, 2017).

- ● ASTM F2912-17 (American Society for Testing and Materials / Standard Specification For Glazing And Glazing Systems Subject To Airblast Loadings, 2017).

- ● ASTM F2248-19 (American Society for Testing and Materials / Standard Practice For Specifying An Equivalent 3-Second Duration Design Loading For Blast Resistant Glazing Fabricated With Laminated Glass, 2019).

In Ukraine, there is an equivalent to the European standard for testing the blast resistance of windows – DSTU EN 13123-1:2006 and DSTU EN 13123-2:2006. The first class of blast resistance corresponds to a window that, after the explosion of 3 kg of TNT at a distance of 5 meters, remains intact and without the formation of fragments inside the room (EXR1 (NS)).

What can you compare 3 kg of TNT to? Russian-made 120 mm caliber mortars have TNT charges ranging from 2.7 kg to 4.9 kg, with most of them containing 3-3.5 kg of TNT9.

The first and second classes of blast resistance provide a significant reduction of approximately 64% in the probability of injury in the event of threats that correspond to the test conditions.

The test conditions in accordance with the standard are provided in the table.

Windows, Doors, and Blinds. Explosion Resistance. Classification and Technical Requirements. Part 2. Test Range. (EN 13123-2:2004, IDT) DSTU EN 13123-2:2006

| Durability class | Explosive charge mass, kg | Distance, m. |

|---|---|---|

| EXR1 | 3 | 5 |

| EXR2 | 3 | 3 |

| EXR3 | 12 | 5,5 |

| EXR4 | 12 | 4 |

| EXR5 | 20 | 4 |

| Note. The test results are further provided with the addition of the S or NS index depending on the presence or absence of fragments that flew out from the reverse side of the tested sample. Example 1. EXR1 (S) - the presence of fragments that flew out from the reverse side of the protective glass or filler material. Example 2. EXR1 (NS) - the absence of fragments that flew out from the reverse side of the protective glass or filler material. | ||

What has been done in Ukraine regarding the testing of windows for blast resistance?

The path has been taken, which can be traced step by step.

Step 1. The first explosion

Testing PVC windows of RC2 class for compliance with two classes of explosion resistance: EXR1 and EXR2 according to DSTU EN 13123.

In the tests of both classes, 3 kg of explosive material in TNT equivalent is used. The difference between the first and second class lies in the distance:

- First class - the explosive is placed at a distance of 5 meters from the window,

- Second class - 3 meters.

"Before the first test explosion at the testing ground, a large number of people were involved. The window was manufactured and assembled with attention to the smallest details described in the Winkhaus documentation and the Vikna-Star recommendations. After the first explosion, it became clear that an extraordinary and highly anticipated event had occurred - the RC2-class window structure withstood the impact wave of the EXR1 explosion-resistant class," Ivan Bohdan reported.

After the first explosion, it became evident that an extraordinary and highly anticipated event had occurred – the RC2-class window structure withstood the impact of the explosive-resistant EXR1-class shockwave.

The assumptions and analysis have been justified.

When selecting window openings for installation and detonation on the firing range, the participants decided not to simplify their lives with a small window, but instead to install a structure like the mass-produced models in Ukraine. They were not studying energy efficiency or sound insulation, but rather more extreme characteristics. Accordingly, a window with a width of 1780 mm and a height of 1460 mm with a mullion was chosen, one part fixed, and the other - tilting. This is as close as possible to the traditional Ukrainian design.

The forces acting on the window due to the shock wave are proportional to the window's surface area. Consequently, a window measuring 1780x1460 mm is designed to withstand 60% greater forces compared to a window measuring 1200x1350 mm. This is a significant difference when dealing with such high loads. If a small-sized window passes the test, it doesn't necessarily mean the same results will apply to larger windows.

It was important to understand how each element of the window behaves: the double glazing and its sealant, hardware, mullion, and mounting fastenings.

As a result of the first test, the structure withstood the load of the first class of explosion resistance. This is a great result and a lot of adrenaline!

Step 2. The bar has been raised

Since the sample of the plastic window passed the first-class explosion resistance test on the first attempt, it was decided to attempt to test another window for second-class explosion resistance when the distance to the explosive device is reduced to three meters.

This test was more challenging. Many weaknesses in PVC structures were identified. Describing them now doesn't make sense.

The result: the prepared sample did not pass the technical test formally. However, from a safety perspective, the structure withstood the load. What's the difference? There were torn corners, issues with the lintel, meaning cracks larger than standard specifications were formed: over 10 mm. But the essence is that the structure held up from the inside: it didn't crumble, and no fragments formed that could have flown into the interior of the building and created problems for people.

The testing process provided a lot of information for analysis. It became clear what weaknesses exist in the windows. It turned out that the risk to humans would be minimal. However, PVC window profiles, which proved to be reliable in the first class, did not withstand the load for the second class of explosion resistance. Reducing the distance by 2 meters with the selected window size proved to be critical.

What's next?

The organizers of the tests received some really cool materials and, first and foremost, very valuable experience. There are videos, photos, a wealth of knowledge, and analytics. All of this would be enough to share new insights with the industry, which is important for everyone. But Ivan and Myhailo decided to do more to ensure that the results are not just recorded research.

As a result, a laboratory that is accredited for this type of testing was successfully located. Experts from the laboratory were invited for the subsequent tests of explosion resistance to ensure compliance with all DSTU requirements.

According to experts from the laboratory, such tests are being conducted in Ukraine for the first time.

And again, negotiations with the military, with the training ground, the development of new structures. The laboratory makes adjustments to what needs to be done during this testing procedure.

This time, it was decided to conduct an explosion not only with a potentially blast-resistant structure but also to film what happens with a regular window: a typical double-glazed window, non-break-resistant hardware, a simple profile system, and so on. To have video and photo documentation of what happens to a regular window during an explosion. Demonstrating the impact of the shockwave on different types of windows provides answers to many questions.

The "standard" window was not the cheapest, with an average price for this category. In this case, it doesn't matter which brands of window components are used; what matters is that the glass is standard, and the window lacks anti-burglary elements. The components are similar to those installed in most windows in Ukraine.

One sample was detonated. The second one was detonated as well. The result is positive. Currently, they are awaiting the laboratory test report, which will state:

Vikna-Star company, which produced window construction systems under the Winkhaus RC2 license and with the experience accumulated by Vikna-Star in the installation, has successfully passed the explosion resistance tests for the first class.'

For the first time in Ukraine!

Step 3. Second class of explosion resistance

Formally unsuccessful tests of the second class of explosion resistance led to further investigations. Since there were moments when the PVC construction couldn't withstand, it was replaced with windows featuring aluminum profiles.

What has been done?

The systems Reynaers MasterLine and SUNRISE (developed specifically for the reconstruction of Ukraine) and RC2 licenses from Winkhaus were used as a basis. Special attention was paid to the insulating glass units and hardware.

This time, representatives from another laboratory with a military focus and extensive experience were invited. They specialize in the explosion resistance of military equipment.

An explosion was conducted with these two aluminum structures. Positive results were obtained for each of them.

So, did the tests answer the question: are RC2 class burglar-resistant windows equivalent to explosion-resistant ones, for example, class one?

The answer is: burglary resistance is the base upon which explosion-resistant windows can be built. However, they are not synonymous.

To claim that a specific RC2 class construction can withstand the load of class one explosion resistance, it is necessary to undergo a testing procedure with representatives from the laboratory who will confirm this.

A total of seven explosive tests were conducted. Each explosion and its result represent an enormous amount of information that is not available anywhere else.

In the context of modern realities, the explosion resistance of windows and doors has ceased to be just an optional feature – it is a requirement of our time to ensure the safety of our clients. Our team of specialists, in collaboration with partners from Winkhaus UA, Reynaers Aluminium, and Glas Troesch, has dedicated many months to conducting extensive tests on our structures to ensure their ability to withstand extreme conditions. The test results and obtained protocols underscore our commitment to creating products that meet the aesthetic requirements of contemporary design and provide security in critical situations.

We plan to revisit this topic on the OKNA.ua platform in the future, so please subscribe to our email newsletter and follow us on social media at OKNA.ua.

Sources:

- BLAST PROTECTION FOR WINDOWS, UN Department of Safety and Security.

- Безпека https://okna.ua/ua/library/bezpeka

- Вікна з протизламністю RC2N https://okna.ua/ua/okna/sc-rc2n

- Кінні, Г.Ф.; Graham, KJ Вибухові удари в повітрі ; Springer: Berlin, Germany, 1985.

- Генріх, Дж. Динаміка вибуху та його використання ; Elsevier: Амстердам, Нідерланди, 1979.

- Mills, C.A. The design of concrete structures to resist explosions and weapon effects. In Proceedings of the 1st International Conference on Concrete for Hazard Protections, Edinburgh, UK, 27–30 September 1987

- Beshara, F.B. Modelling of blast loading on aboveground structures—I. General phenomenology and external blast. Comput. Struct. 1994, 51, 585–596

- BLAST PROTECTION FOR WINDOWS, UN Department of Safety and Security.

- 120-мм возимый миномёт 2Б11 https://w.wiki/7j66

- https://w.wiki/7j6A