Complex parametric free-form facades

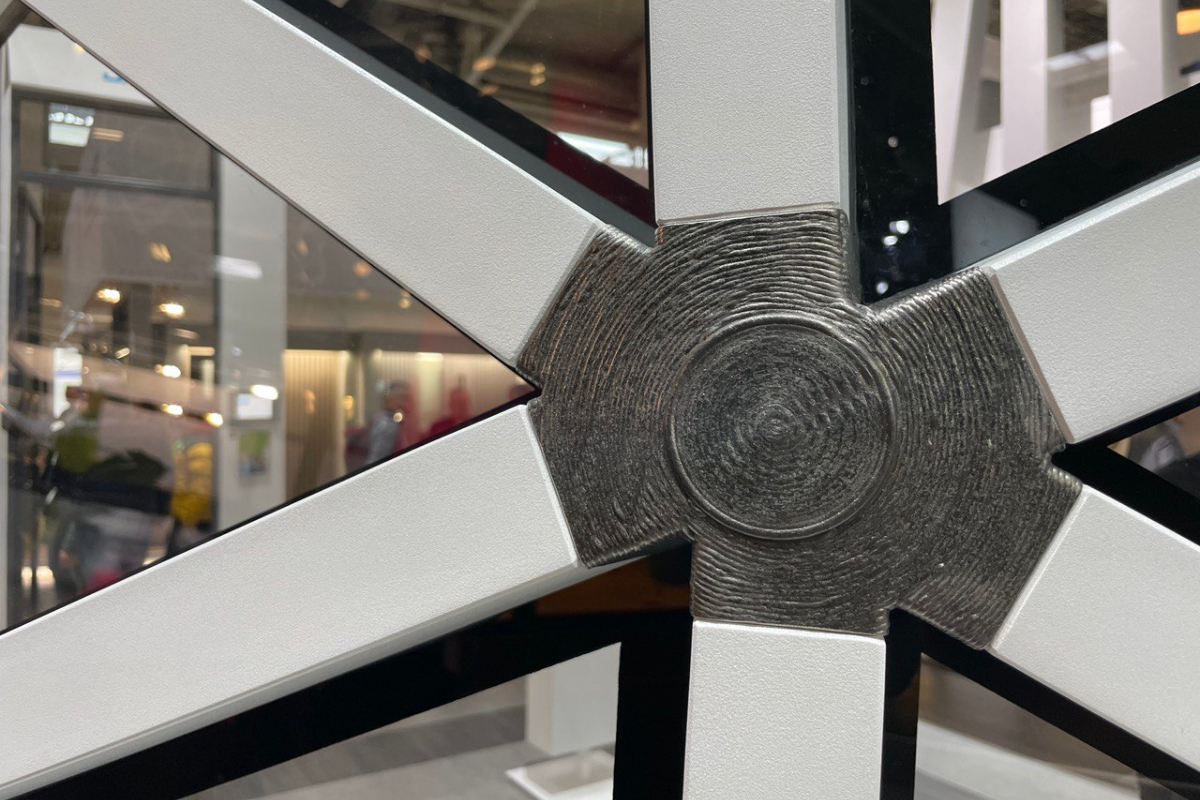

3D printing of steel nodes for Jansen's facades

Innovators from the Swiss company Jansen are using a metal 3D printer to create steel facade nodes. This is the result of a research collaboration between the Dutch TU Delft, German engineering company knippershelbig GmbH, Austrian MG Metalltechnik GmbH and Jansen. The results of the work were presented at the BAU 2023 global construction exhibition in Munich.

Any connection corresponds to the load on the facade or roof with a multiplied safety factor. Because every new element cannot be tested for compliance with building requirements.

The Jansen façade is an example of a qualitative upgrade of the capabilities of a traditional system. It allows architects to implement new forms and create free-form facades.

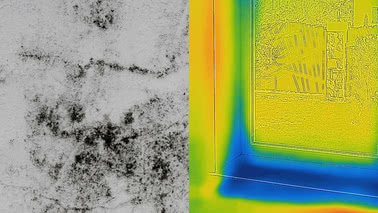

Schüco Grid2Shell free-form facade

Schuco took advantage of the BAU trade fair to present the self-supporting aluminium facade Grid2Shell.

Each unit make individually for the project. During production, the nodes are numbered and labelled to facilitate installation. The support profiles screw to the nodes at the marked point. No additional welded joints are required.

Schueco Grid2Shell allows for three-dimensional roof and façade structures without steel substructures. You can create a smooth transition from the vertical level of the façade to the roof area.