VEKA Euroline AD

Window profile system Euroline AD

Brand VEKA

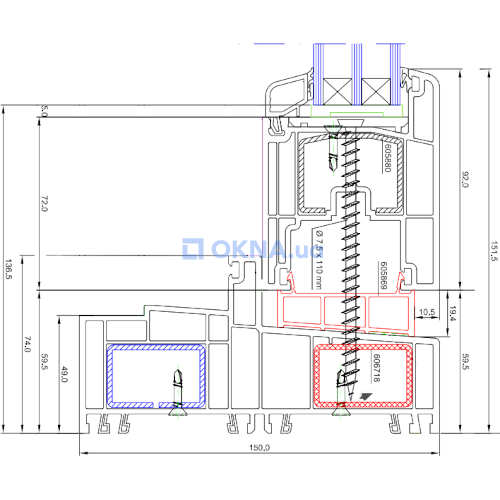

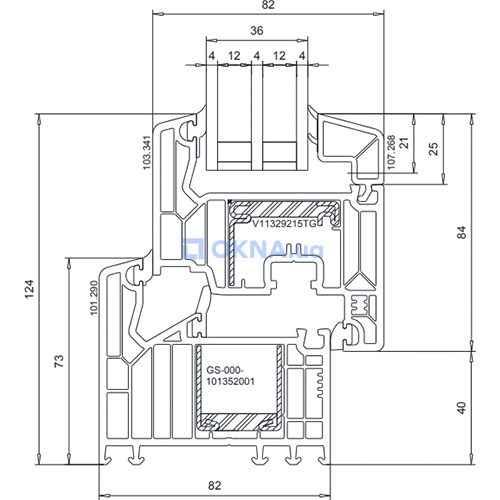

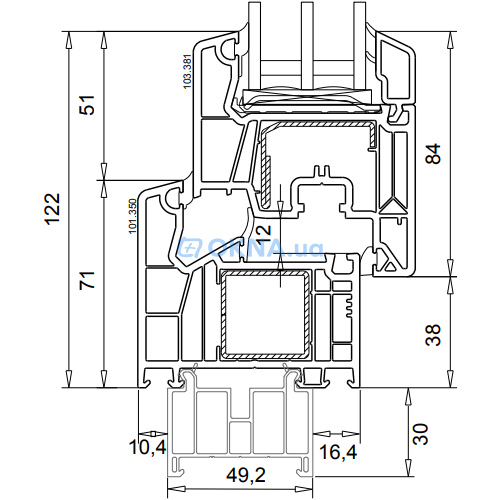

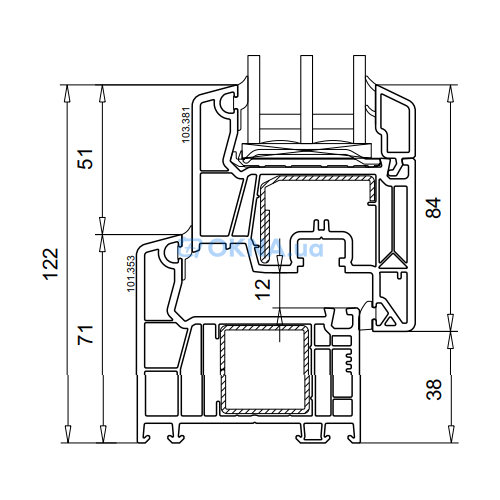

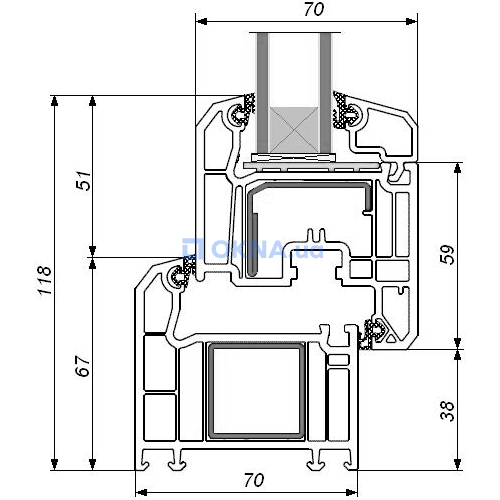

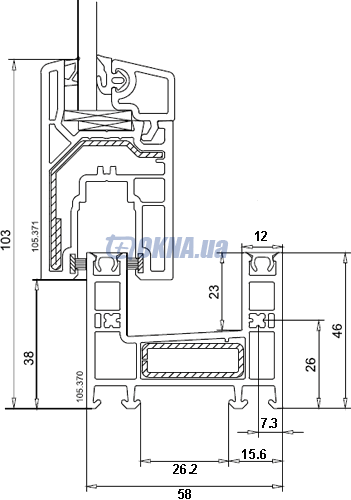

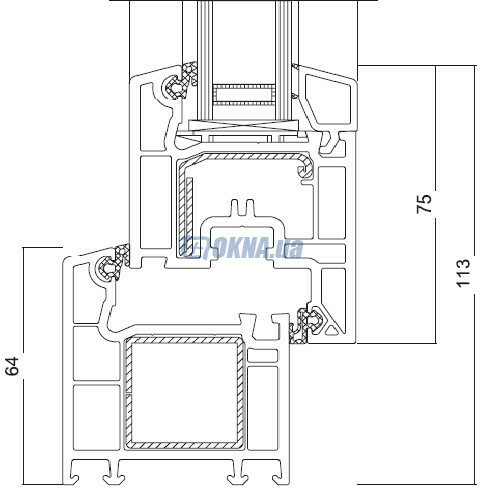

| Outer width of the frame | 58 mm | |

| Uf profile | 1.64 W/Km² | |

| Glass unit thickness | 32 mm |

| Outer width of the frame | 58 mm |

| U Factor of profile system (armoured if applied) | 1.64 W/Km² |

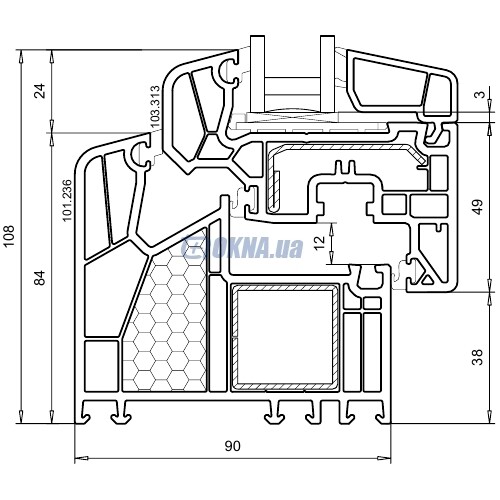

| Thickness of outer wall | 3 mm |

| Number of chambers in the frame | 3 |

| Number of chambers in the sash | 3 |

| Max width of a glass unit | 32 mm |

| No. of sealing circuits | 2 |

| Material | vinyl profiles |

| Type of system design (AD, MD) | AD |

| Turn constructions' fittings | yes |

| Tilt and turn constructions' fittings | yes |

| Horizontal sliding constructions' fittings | yes |

| Turn balcony doors fittings | yes |

| Tilt and turn balcony doors fittings | yes |

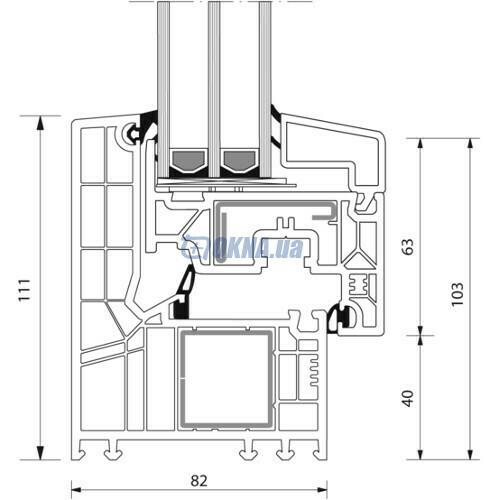

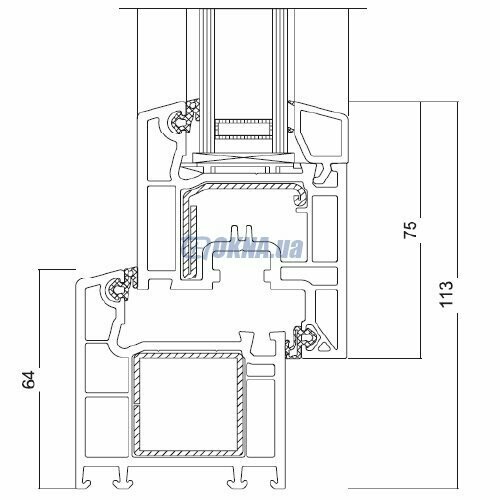

| Fixed window light blocking | 64 mm |

| Sash window light blocking | 113 mm |

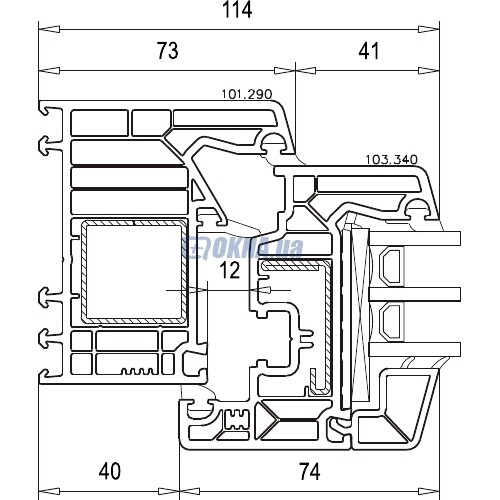

| Double-leaf sash window light blocking | 40 mm |

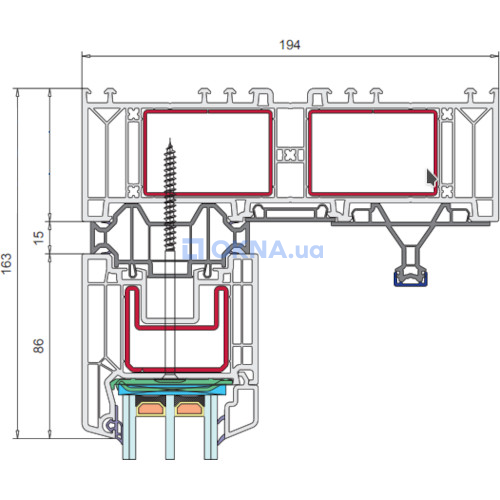

| Transom window light blocking | 82 mm |

| Transom bar + 2 sashes window light blocking | 180 mm |

| Surface: lamination | yes |

| Sound insulation | 44 dB |

| The Ukrainian certificate | yes |

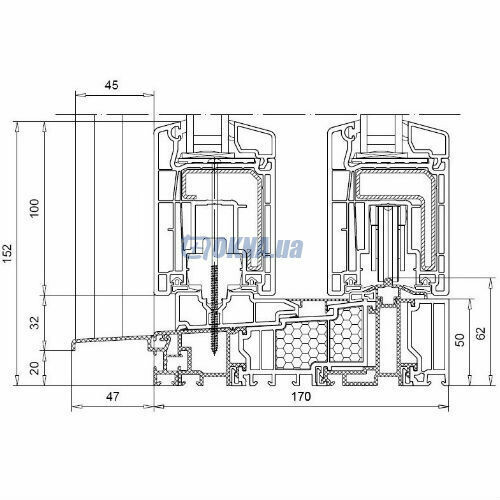

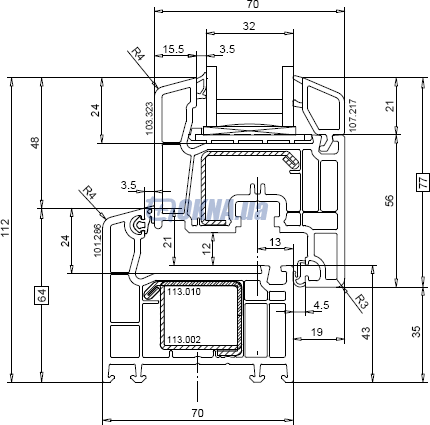

The company VEKA AG switches to system SOFTLINE and EUROLINE axial 13 mm and adapts thus the axial dimension to the already existing system TOPLINE, having a mounting width of 70 mm. All of the new system, further, that the firm VEKA AG will develop in the near future, this will also have an axial dimension that will give the company VEKA partners a number of advantages.

Thus, this change makes it possible to use the same system EUROLINE packings are used in systems VEKA, having wiring width of 70 mm. With such a high degree of compatibility between systems eliminates the need to have in stock a large number of different seals. This also applies to stocks of various components of the hardware, which can now be used for both systems, the company VEKA, having a mounting width of 58 mm, and for systems with installation width of 70 mm.

By further developing the system, the size of the groove bead EUROLINE now the same as the company VEKA systems, having a mounting width of 70 mm. There are also advantages with respect to storage on stock hardware, for example, the same lock, which can now be used in all systems company VEKA. Due to a further change in overlapping flaps greatly facilitate the process of fixing screws and hardware optimized cleaning process. Fillet of EUROLINE was also redesigned. Now it comes with a coextruded gasket made of soft PVC. After conducting a comprehensive series of tests consistently high product quality is guaranteed.

Thus, when the system appears EUROLINE several advantages, especially for processing of a technical nature which seek to achieve the most efficient production. Same height racks allows parallel processing system EUROLINE and TOPLINE. Optimal application ensures minimal installation height, which allows the architect to design the window with the "narrow" frames at the respective sites. Excellent static performance, which is achieved with the system EUROLINE, meet all the requirements to object construction. It should be noted, first of all, thanks to a reinforced leaf optimally calculate the size of the cameras, as well as double reinforcement.

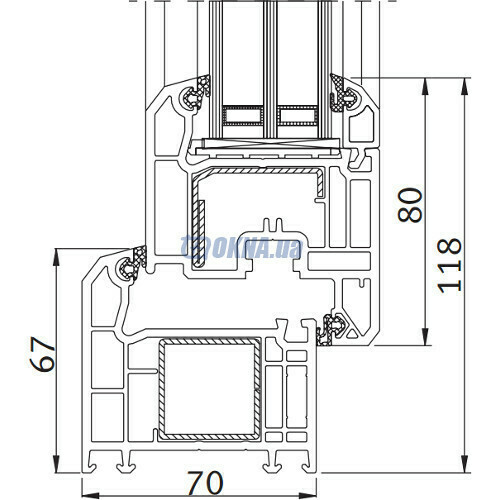

Along with the improvement of EUROLINE, it has also been redesigned system TOPLINE. The result of this processing is a real five - chamber system with a mounting width of 70 mm. A secondary camera provides improved energy efficiency and has excellent static performance. As in the colored and white profiles will now be used the same casement profile. Partner of the firm VEKA cares about the appropriate application at the disposal of the steel reinforcement to ensure appropriate amplification profile.

Thus, this change makes it possible to use the same system EUROLINE packings are used in systems VEKA, having wiring width of 70 mm. With such a high degree of compatibility between systems eliminates the need to have in stock a large number of different seals. This also applies to stocks of various components of the hardware, which can now be used for both systems, the company VEKA, having a mounting width of 58 mm, and for systems with installation width of 70 mm.

By further developing the system, the size of the groove bead EUROLINE now the same as the company VEKA systems, having a mounting width of 70 mm. There are also advantages with respect to storage on stock hardware, for example, the same lock, which can now be used in all systems company VEKA. Due to a further change in overlapping flaps greatly facilitate the process of fixing screws and hardware optimized cleaning process. Fillet of EUROLINE was also redesigned. Now it comes with a coextruded gasket made of soft PVC. After conducting a comprehensive series of tests consistently high product quality is guaranteed.

Thus, when the system appears EUROLINE several advantages, especially for processing of a technical nature which seek to achieve the most efficient production. Same height racks allows parallel processing system EUROLINE and TOPLINE. Optimal application ensures minimal installation height, which allows the architect to design the window with the "narrow" frames at the respective sites. Excellent static performance, which is achieved with the system EUROLINE, meet all the requirements to object construction. It should be noted, first of all, thanks to a reinforced leaf optimally calculate the size of the cameras, as well as double reinforcement.

Along with the improvement of EUROLINE, it has also been redesigned system TOPLINE. The result of this processing is a real five - chamber system with a mounting width of 70 mm. A secondary camera provides improved energy efficiency and has excellent static performance. As in the colored and white profiles will now be used the same casement profile. Partner of the firm VEKA cares about the appropriate application at the disposal of the steel reinforcement to ensure appropriate amplification profile.