PROFILCO PR72

Window profile system PR72

Brand PROFILCO

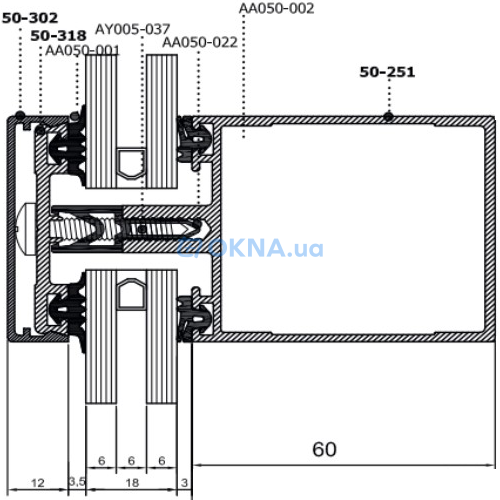

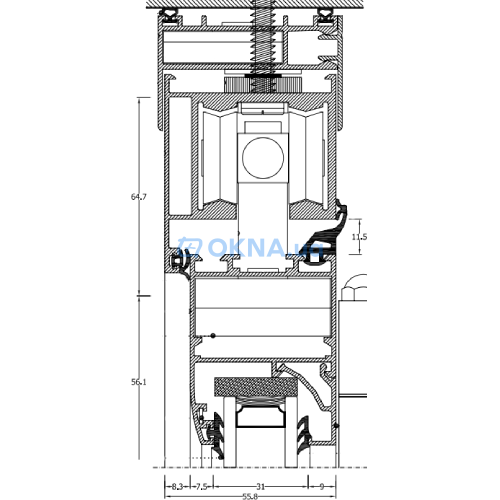

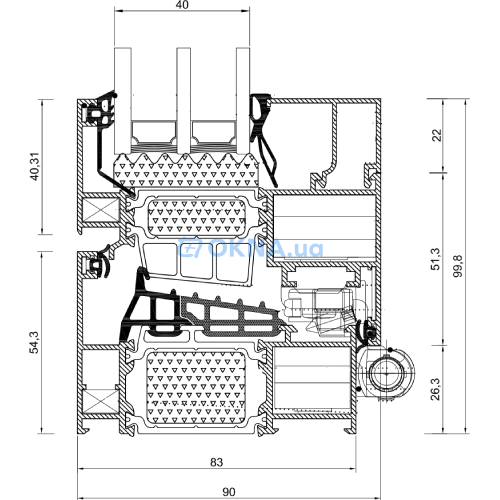

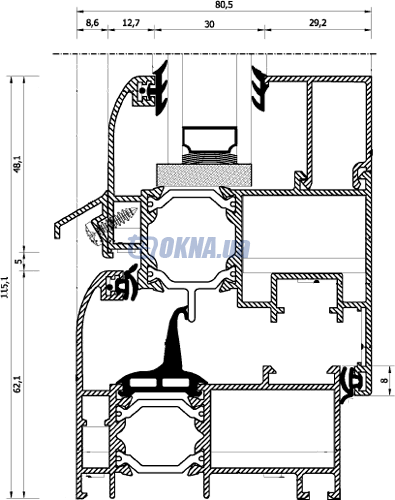

| Outer width of the frame | 72 mm | |

| Uf profile | 3.37 W/Km² | |

| Glass unit thickness | 30 mm | |

| System production accomplishment | 2023 year |

| Outer width of the frame | 72 mm |

| U Factor of profile system (armoured if applied) | 3.37 W/Km² |

| Thickness of outer wall | 1.4 mm |

| Number of chambers in the frame | 3 |

| Number of chambers in the sash | 3 |

| Max width of a glass unit | 30 mm |

| No. of sealing circuits | 3 |

| Material | aluminium profiles |

| Type of system design (AD, MD) | MD |

| Turn constructions' fittings | yes |

| Tilt and turn constructions' fittings | yes |

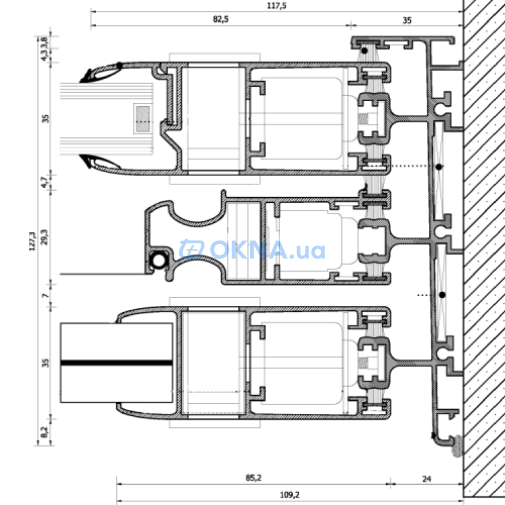

| Turn balcony doors fittings | yes |

| Tilt and turn balcony doors fittings | yes |

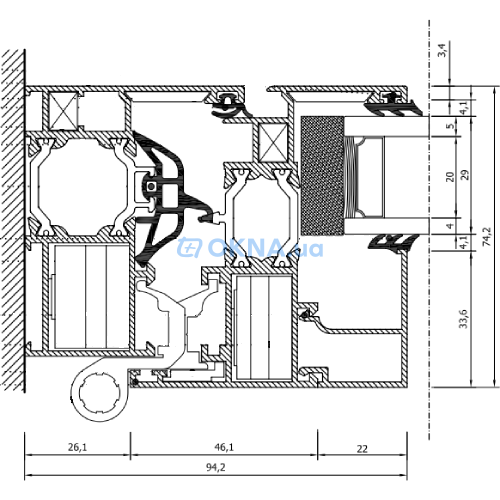

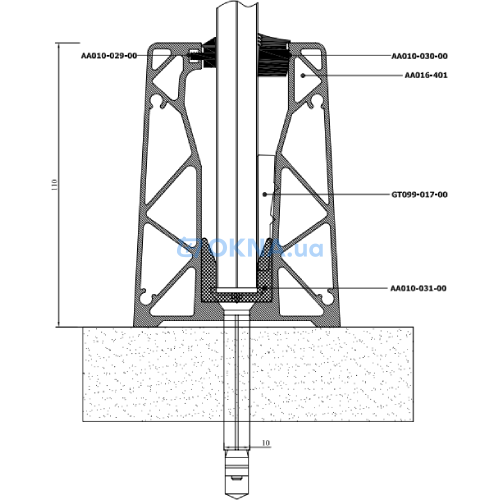

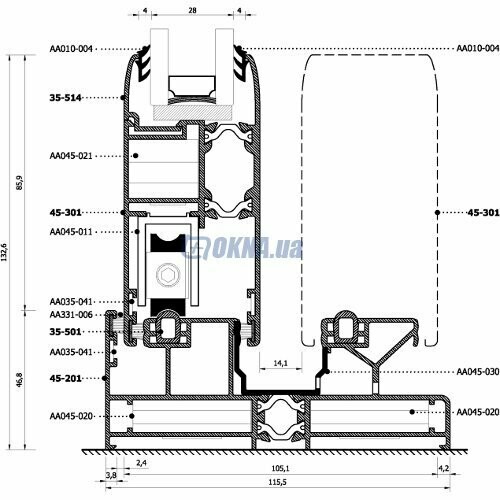

| Fixed window light blocking | 62.1 mm |

| Sash window light blocking | 115.1 mm |

| Double-leaf sash window light blocking | 73.5 mm |

| Transom window light blocking | 93.5 mm |

| System production accomplishment | 2023 year |

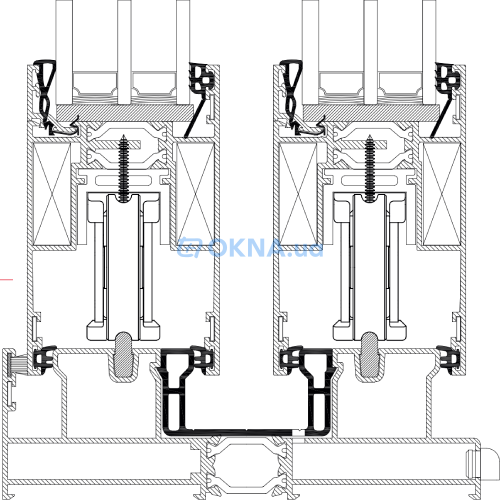

PROFILCO company to meet the high requirements for aluminum systems of its customers has created a new system with thermal PR72, which uses the hardware used in the production of plastic windows.

The design of this system was created based on all leading systems PROFILCO, to which were added the benefits of hardware used in the plastic industry. PR72 is a high quality profile system that provides absolute protection from cold, heat, noise and creates ideal conditions indoors.

Main features of PR72:

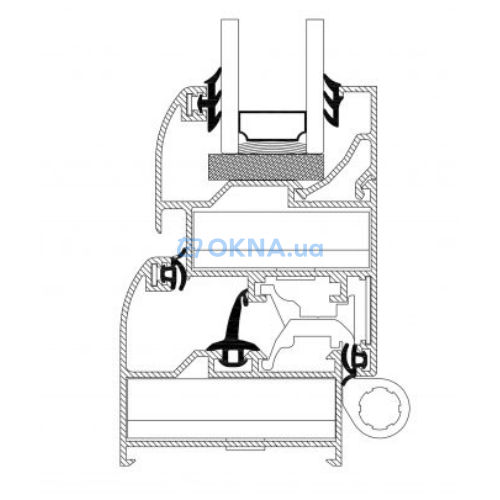

* Installation of special steel bollards around the perimeter of the window binding to ensure the reliability design.

* Easy installation, does not require a lot of time and financial costs.

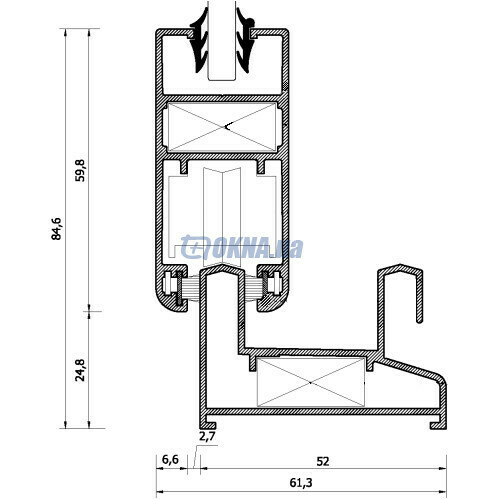

* The width of the window binding 72 mm.

* Use the special 24mm polyamide thermal bridge.

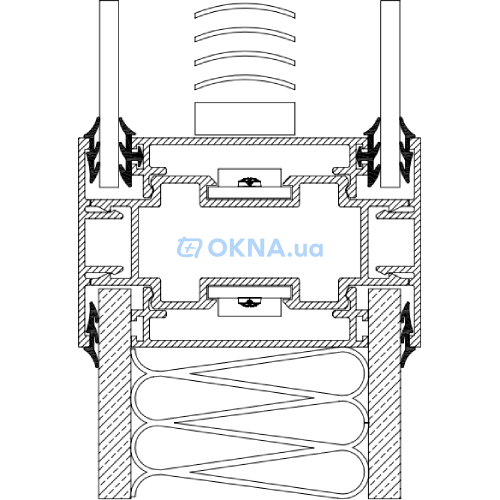

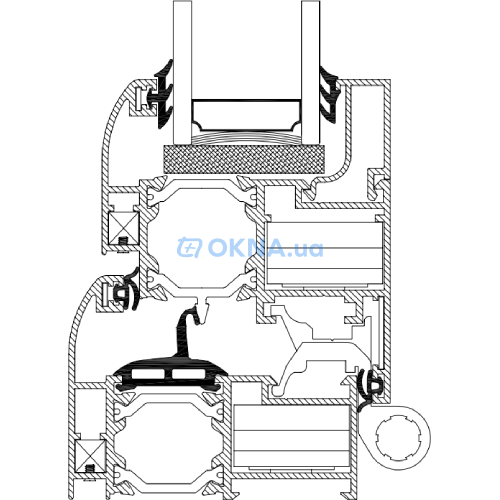

* The central gasket is made of EPDM rubber with overlaps 5-8mm on leaf profile that provides complete sealing opening portions.

* Seals made of rubber EPDM soft for easy installation of its profile.

* For better sealing of leaf comes to the frame 8mm.

* Fastened EPDM rubber frame and sash.

* Central EPDM rubber is vulcanized corner joint that avoids leaking.

* Minimum thickness profiles of 1,4 mm.

* Drainage channels are punched in all profiles the frame and sash.

* Thickness, increasing in some places the profile required for safety.

* Compound profiles can be done manually (mechanically) using pins, and through the press.

* Specially designed corner joints for the frame and sash for loads up to 130 kg.

* New manual press, which in addition to the basic functions have additional opportunities to make holes in the frame for a loop. This prevents undesired breakage of the drill, which are observed during the use of the plates for drilling, production and drainage of the frame.

The design of this system was created based on all leading systems PROFILCO, to which were added the benefits of hardware used in the plastic industry. PR72 is a high quality profile system that provides absolute protection from cold, heat, noise and creates ideal conditions indoors.

Main features of PR72:

* Installation of special steel bollards around the perimeter of the window binding to ensure the reliability design.

* Easy installation, does not require a lot of time and financial costs.

* The width of the window binding 72 mm.

* Use the special 24mm polyamide thermal bridge.

* The central gasket is made of EPDM rubber with overlaps 5-8mm on leaf profile that provides complete sealing opening portions.

* Seals made of rubber EPDM soft for easy installation of its profile.

* For better sealing of leaf comes to the frame 8mm.

* Fastened EPDM rubber frame and sash.

* Central EPDM rubber is vulcanized corner joint that avoids leaking.

* Minimum thickness profiles of 1,4 mm.

* Drainage channels are punched in all profiles the frame and sash.

* Thickness, increasing in some places the profile required for safety.

* Compound profiles can be done manually (mechanically) using pins, and through the press.

* Specially designed corner joints for the frame and sash for loads up to 130 kg.

* New manual press, which in addition to the basic functions have additional opportunities to make holes in the frame for a loop. This prevents undesired breakage of the drill, which are observed during the use of the plates for drilling, production and drainage of the frame.