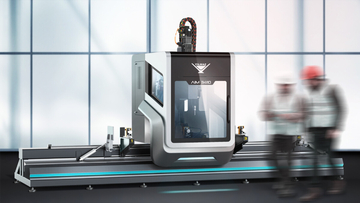

Edgetech Europe has announced that the automatic production line for triple insulating glass units with ultra-thin middle glass (Skinny Triples) using the warm edge spacer Super Spacer® is ready to enter the market. In cooperation with the Italian machinery manufacturer Forel, the company presented a technology that enables the production of “slim” triple insulating glass units without the need for multi-million investments.

Glas Trösch also presented an insulating glass unit with ultra-thin glass at BAU 2025.

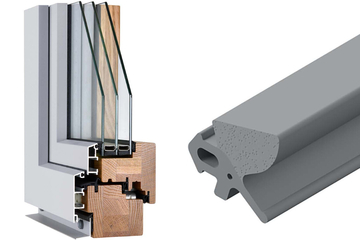

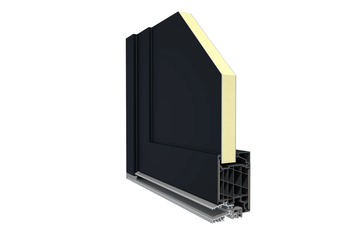

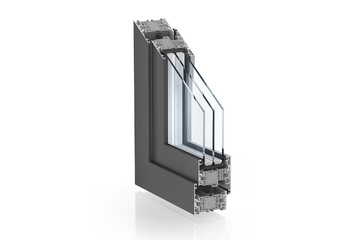

A traditional triple insulating glass unit consists of three full glass panes forming two insulating cavities. In contrast, the Skinny Triples feature an ultra-thin inner glass with a thickness of 0.7 to 1.3 mm filled with krypton. This ensures high thermal insulation at a lower weight. According to Mike Moran, Vice President of Sales at Edgetech/Quanex, the use of Super Spacer® allows the thin glass to be integrated with precision of less than a millimetre, increasing quality and competitiveness in the window renovation segment.

The modified Forel High Speed Line, first shown at Glassbuild 2024, makes it possible to manufacture triple insulating glass units compatible with 70 mm profile systems.

Edgetech Europe products and Forel equipment will be presented at the international exhibition Vitrum 2025, which will take place in Italy from 16 to 19 September. According to Edgetech (UK) Ltd, the production line for thin triple insulating glass units in the United Kingdom will start operating by the end of 2025.

Photo: Edgetech (UK) Ltd

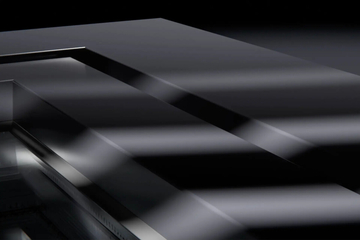

Forel High Speed Line — a fully automated production line for the manufacture of thin triple insulating glass units

Automatic line for the production of insulating glass units with ultra-thin glass and warm edge Super Spacer ready to enter the European market

ID no: 23872

Feb 5, 2026

Feb 3, 2026

Today 18:54

Today 18:23

Today 16:44