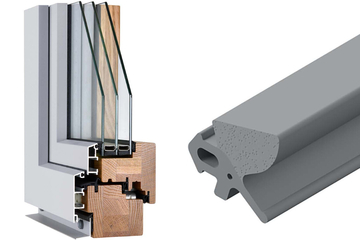

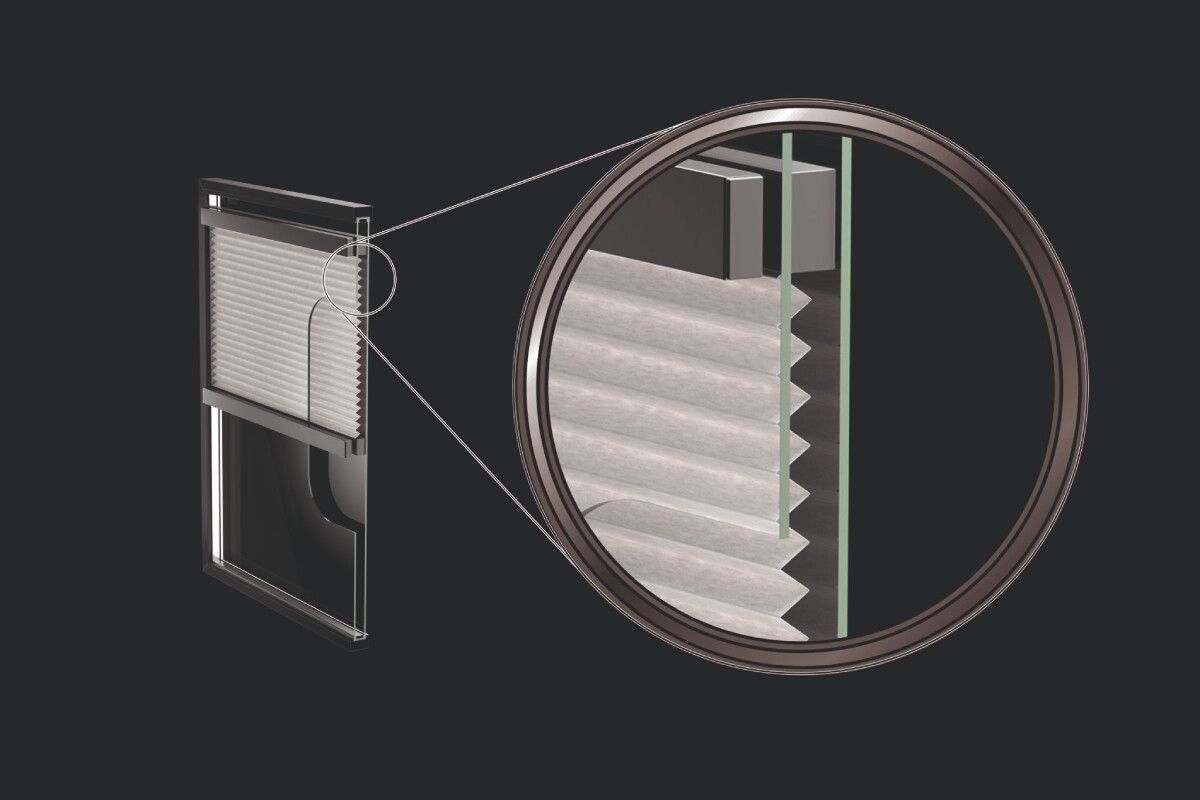

The German company isophon glas GmbH has patented the isoplix insulating glass unit with integrated pleated blinds operated via magnetic strips. According to the company, the system is specifically designed for rooms with high hygiene requirements, such as hospitals, care homes, laboratories, and food production facilities.

Unlike conventional roller blinds and shutters, which are prone to dirt and mechanical damage, the blinds in the isoplix system are integrated directly into the insulating glass — into the space between the panes. This protects them entirely from dust, dirt, and touch, which is particularly important in medical and sanitary facilities.

The system is operated using magnetic strips positioned on the inner side of the window. The user can conveniently move the blinds into any position — fully closed, or left open at the top or bottom. This enables flexible control of lighting and privacy without the need for cleaning the blinds themselves.

As explained by Torsten Bold, the owner of isophon glas GmbH, one of the challenges was enabling magnetic operation. The glass on the inner side of the window, along which the magnetic strips move, must be no thicker than 4 mm. In exceptional cases, a 5 mm thickness is acceptable. The blinds themselves are made from a special, nearly opaque fabric with a partially reflective coating.

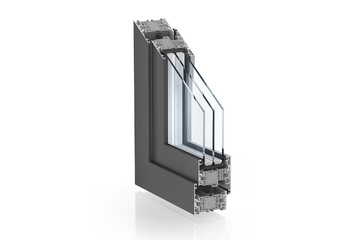

isoplix is a standard insulating glass unit also available with laminated safety glass, burglar resistance, or sound insulation. There is a minor limitation: the cavity with the pleated blind must be 16 mm thick.

The company offers various isoplix sizes: width from 200 to 1200 mm, height from 200 to 2200 mm.

Previously, isophon glas GmbH introduced a burglar-resistant insulating glass unit with polycarbonate for panic exit doors.

Photo: isophon glas GmbH

Sun protection is safeguarded from all forms of dirt

German company develops insulating glass units with integrated pleated blinds on magnets

ID no: 23731

Jan 28, 2026

Jan 23, 2026

Today 16:44

Feb 5, 2026