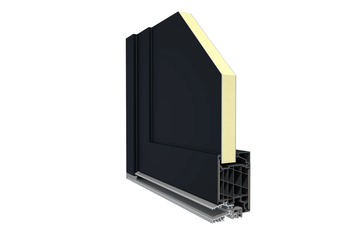

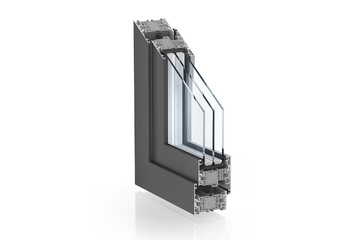

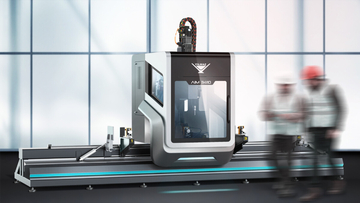

The German profile system manufacturer Schüco has presented the new CC 800 crimping machine, which performs automatic corner processing of aluminium frames from all four sides. According to the company, the equipment provides a consistent production speed – one frame every 70 seconds.

The Schüco CC 800 machine supports the processing of profiles up to 250 mm in height, including those with pre-inserted gaskets. The system automatically compensates for tolerances, reads barcode and data matrix codes, and operates under the control of SchüCal. Depending on the size, the machine can handle both small windows of 380×420 mm and large constructions up to 4000×6500 mm.

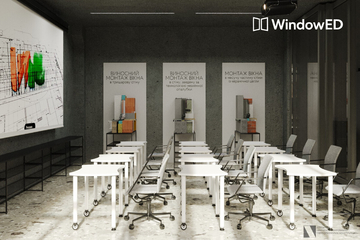

The company notes that the equipment is suitable for both custom production workshops and linear series production of windows, doors, and façades. Thanks to predictive maintenance and pneumatic monitoring, Schüco expects high reliability and long service life from the CC 800.

This machine follows the trend of increasing automation in profile processing equipment. Recently, Elumatec also introduced the new DG 102-P end milling saw for serial production of windows and doors.

Photo: Schüco International KG

The Schüco CC 800 can be integrated into various workshop layouts and is especially well-suited to linear production lines

Schüco introduces the four-head corner crimping machine CC 800 with automatic feed

ID no: 23809

Feb 5, 2026

Feb 3, 2026

Jan 28, 2026

Today 18:23