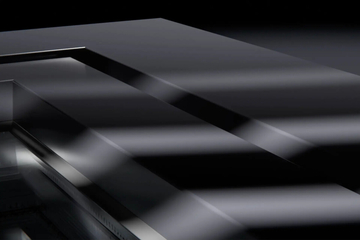

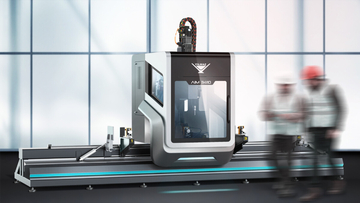

The German manufacturer of large-format insulating and safety glass Sedak GmbH & Co. KG has unveiled the sedak multicurved technology, which enables glass to be bent into complex 3D shapes while simultaneously being thermally strengthened. The premiere took place at Glass Performance Days 2025, where the company demonstrated the ability to produce tempered glass in unconventional shapes, free from the constraints of traditional mould-based processes.

The technology is based on controlling the firing process in the furnace, where the glass takes on the desired geometry without the restrictions imposed by moulds. This makes it possible to create multi-curved, cylindrical and even spherical geometries.

“We are entering the next generation of glass bending — custom manufacturing of products with non-standard geometry without the use of moulds,” says Kevin Berni, Sedak’s Sales Director.

According to the company, removing these limitations enables faster order fulfilment, scaling up the production of complex shapes and offering greater design freedom.

Photo: sedak

The glass can be bent multi-axially — in several directions — and tempered at the same time

sedak presents simultaneous glass bending and tempering technology

ID no: 23860

Feb 5, 2026

Feb 3, 2026

Jan 28, 2026

Today 18:23

Today 16:44