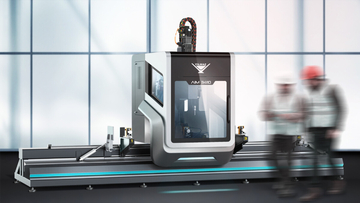

Roto Frank Fenster- und Türtechnologie GmbH has announced the launch of its global production system “ROPEX” at all 18 of its sites. According to the company, this marks a new stage in its manufacturing strategy, combining global standards with local characteristics. The system is aimed at increasing efficiency, ensuring consistent product quality and meeting the group’s climate targets in production.

Roto FTT’s Director of Global Operations, Dr Stefan Thiemermann, explains: “‘ROPEX’ is a production system that links our strategic goals with operational excellence. It is standardised worldwide but can be adapted to local conditions.” According to him, for window and door manufacturers this means stable processes, top quality and reliable supply.

A key element of “ROPEX” is the Kaizen principle – continuous improvement in small but effective steps. “Our goal is to accelerate Kaizen, implement improvements more quickly and achieve measurable results,” emphasises Roto FTT’s Head of Production and Technology Management, Stephan Strohbücker.

The system is based on four core principles: zero defects, value stream, flexibility and transparency. These are complemented by methods such as shop floor management, workplace design, visual management and other tools. All Roto plants work according to common principles, creating transparency, comparability and a shared production language.

The introduction of “ROPEX” makes it possible to spread best practices throughout the global production network.

Read more about how other market players are improving their production sites in the news: MACO collects awards for its “Get rid of gas” industrial project.

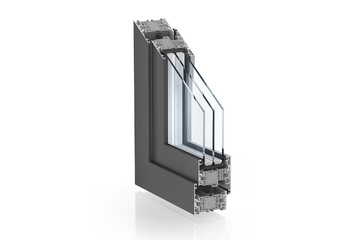

Photo: Roto FTT

Roto Frank Fenster- und Türtechnologie GmbH’s goal is to strengthen competitiveness through optimised processes at all 18 plants of its corporate group

Roto launches new ROPEX production system at all plants

ID no: 23923

Feb 5, 2026

Feb 3, 2026

Jan 28, 2026

Today 18:23

Today 16:44