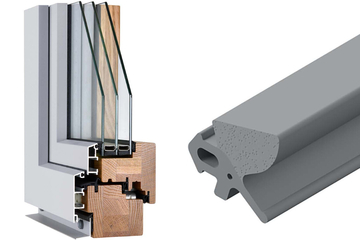

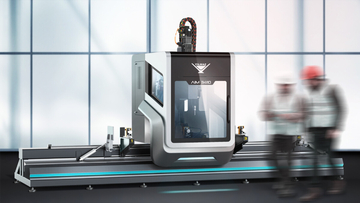

The Italian equipment manufacturer Forel together with the American warm-edge spacer producer Quanex showcased the new automated DuraLine line at GlassBuild America 2025. The new solution provides high speed, precision and consistent quality when producing insulating glass units with Duralite and Duraseal spacers.

Forel designed DuraLine to maximise line productivity while ensuring all key requirements for applying spacer systems that do not require secondary sealing, such as Duralite and DuraSeal.

The new DuraLine line covers the entire production process – from spacer application to sealing and automatic gas filling.

Among the key advantages, the developer highlights precise spacer application as well as simultaneous perimeter heating to the required temperature to ensure reliable adhesion. Gas filling and final assembly are performed automatically with accurate alignment of the insulating glass unit and correct filling of the cavity.

The line typically requires 3–4 operators.

Forel notes that automation means fewer errors, less manual adjustment and consistent quality in every insulating glass unit.

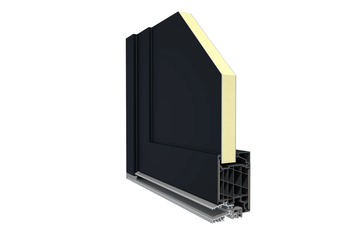

Another automated Forel line for producing insulating glass units with ultra-thin glass and the Super Spacer warm-edge system is ready to enter the European market.

Photo: Forel

Forel DuraLine — optimisation at every stage: from applying the spacer frame to gas filling

Forel and Quanex introduce the new automated DuraLine line for fast and precise insulating glass production

ID no: 23986

Feb 5, 2026

Feb 3, 2026

Today 18:54

Today 16:44