REHAU is actively promoting a circular economy in window manufacturing. Through the EcoPuls initiative, the company collects old plastic windows across Europe. Over 1,200 partners have joined the system, ensuring the regular collection of old PVC products. Recycling takes place at facilities in Śrem, Poland; DEKURA in Germany; and PVC-R in the United Kingdom. All plants are certified by VinylPlus. The old windows are separated into PVC, glass, and metal.

REHAU’s own logistics system enables the transport, recycling, and granulation of old profiles with a minimal carbon footprint. This allows up to 88% reduction in CO₂ emissions compared to the production of virgin PVC. The company notes the importance of its REHAU Window.ID system — a digital identification that “accompanies” the window throughout its life cycle and facilitates further disposal and recycling.

In 2024, the company invested in expanding its co-extrusion capacity and modernising recycling lines.

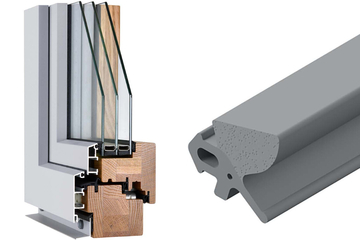

REHAU also listed the following as its core systems in Europe and the US:

- ARTEVO / GENEO — profiles made from RAU-FIPRO X composite, offering strength and thermal insulation without the need for steel reinforcement.

- SYNEGO — versatile profiles with excellent thermal and acoustic insulation.

- BRILLANT / Euro-Design 70 — with a wide range of design options.