Recycling of used aluminium scrap and production waste uses only 5% of energy compared to the production of primary materials. Europe also has the potential for secondary aluminium resources with an expected share of 49% of total aluminium production by 2050. Therefore, the new project aims to maximise the potential of this resource as part of decarbonisation.

The challenge is the alloy composition, which makes separation difficult.

RecAL is focusing on developing recycling and digital technologies to promote a circular economy of aluminium:

- developing alloys with increased resistance to impurities without compromising performance,

- use of digital and robotic technologies for sorting and dismantling,

- production of high-purity materials,

- adaptation of production processes to use secondary resources,

- harmonisation of cooperation between aluminium industry players.

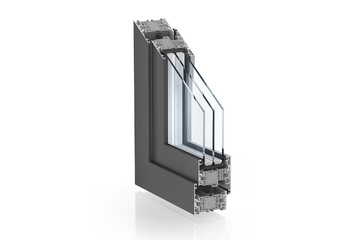

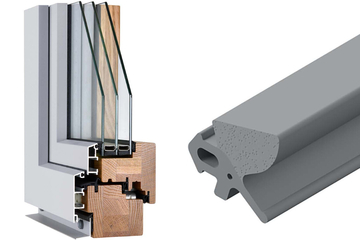

Alumil has already launched the recycled aluminium profile Loop60 for architectural systems. It consists of 60% recycled material. The company will share this experience with its partners.

RecAL started in January 2024 and will last until December 2027. 19 participants have already joined the project. They plan to improve 14 important technological solutions and bring them to the level of technological readiness.