This year, companies Winkhaus UA, Glas Trösch Ukraine, Reynaers Aluminium Ukraine, and "Vikna-Star" continued research aimed at enhancing the windows' resistance to shock waves.

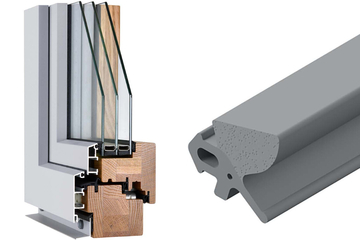

One of the achievements was the production of a plastic window that successfully passed the tests and confirmed the EXR2 blast resistance class. The construction is made from PVC profile with an aluminum external overlay, which added the necessary rigidity. It features Winkhaus activPilot burglar-resistant hardware. The double-glazed unit from Glas Trösch includes P4A triplex glass — two panes of 4 mm thickness and four layers of PVB film (autoclave lamination). According to DSTU EN 356:2005, the highest resistance category is P5A. The glass unit is adhered with a special sealant, with correctly selected fasteners and proper installation.

During the tests, various window constructions were subjected to controlled explosions to evaluate their resistance. The results also showed that a regular window with an applied "armor film" does not provide adequate protection, as during an explosion, the glass unit breaks and enters the premises, creating debris. In contrast, licensed blast-resistant windows remained intact without producing hazardous debris.