Schüco has unveiled a new generation of EasySlide sliding systems. Developed for renovation projects, the system offers improved thermal insulation and burglary protection up to RC2. In its standard configuration, the average Uf value is 1.47 W/(m²K).

Schüco placed particular emphasis on environmental sustainability. The new EasySlide generation can incorporate bio-PVC — a material produced using tall oil instead of crude oil. Tall oil is a by-product of paper production from coniferous trees and does not compete with the food chain. This approach can reduce CO₂ emissions by up to 90% compared to conventional virgin PVC. The manufacturing process is certified by RSB and ISCC PLUS, ensuring supply chain transparency.

A similar approach has been demonstrated in the REHAU ARTEVO TERRA system, which combines bio-PVC in the outer profile layer with recycled PVC in the core.

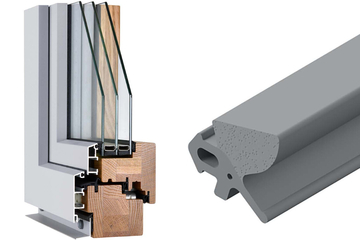

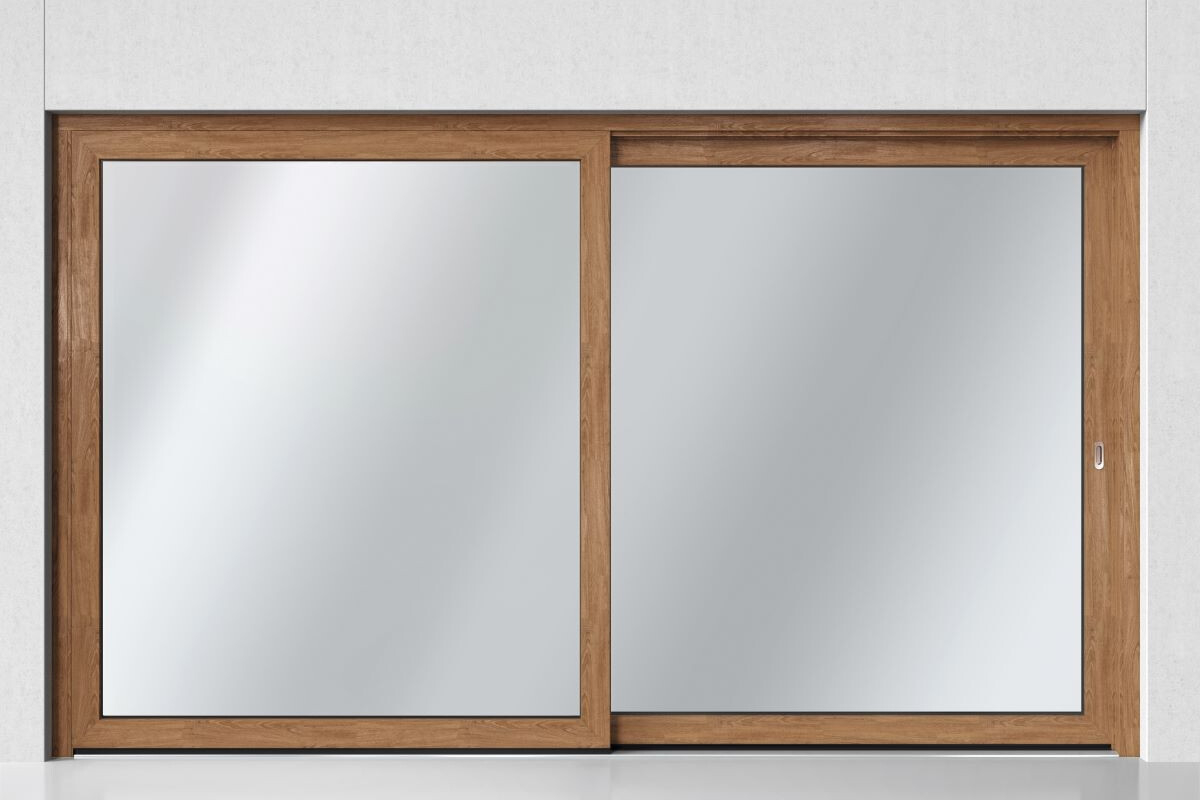

Schüco EasySlide is based on the 70 mm Schüco CT 70 system platform. It accommodates glazing units up to 40 mm thick.

Key benefits include a minimal number of components and simplified fabrication. Many parts are standardised, and components such as roller carriages are installed without additional processing around the fixing groove of the lift-and-slide vent frame. This saves time, and the reinforcement chamber of the vent frame remains fully enclosed, allowing for uniform steel cross-sections to be used.

Photo: Schüco International KG

With a basic vent depth of 70 mm and a frame depth of 167 mm, Schüco EasySlide is well-suited for renovation projects

New generation of Schüco EasySlide sliding systems can be made with bio-PVC

ID no: 23655

Jan 28, 2026

Jan 23, 2026

Feb 5, 2026

Feb 3, 2026