At this year's glasstec exhibition, LiSEC, a supplier of glass processing equipment, will present robotic unloading systems.

Glass manufacturers are compelled to improve the efficiency of production processes, eliminate bottlenecks, and increase automation, particularly due to a shortage of skilled personnel. In response to these needs, LiSEC has focused on developing equipment that accommodates the increasing size and weight of glass sheets, as well as the need for more flexible and automated production.

To address the shortage of skilled workers, Ukrainian businesses, for example, have agreed to cooperate in developing a vocational education system.

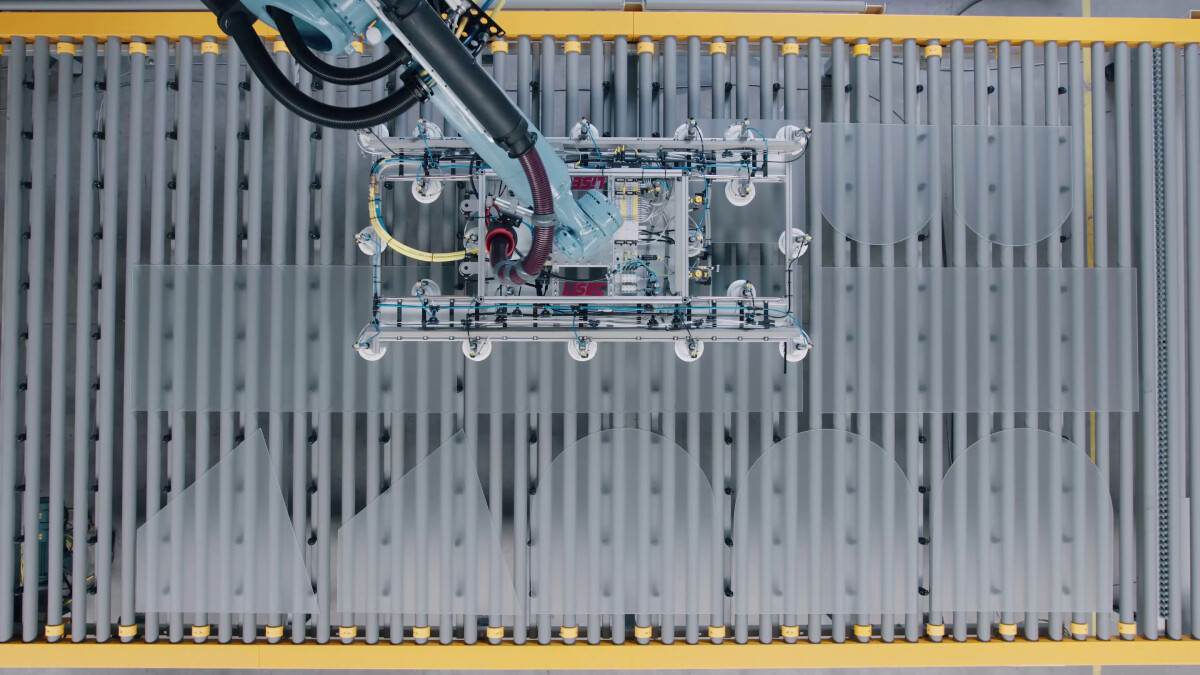

The company will use glasstec 2024 in October to demonstrate a robotic glass unloading station in action, which includes a rotating carousel for A-frames. The system allows glass sheets to be unloaded in a horizontal orientation and vertically onto a frame. During unloading, two stacks are formed on each side of the A-frame. Thanks to precise robotic control, this system ensures a continuous unloading process for the LSG glass cutting line.

According to LiSEC representatives, robotic systems allow for the optimization of existing production lines without the need to change the shop floor layout. They help minimize errors and glass damage.

Photo: LiSEC

Robotics increase workplace safety and minimize physical strain on employees.

LiSEC to Showcase Robotic Unloading System at glasstec 2024

ID no: 23315

Jan 28, 2026

Jan 23, 2026

Today 16:44

Feb 5, 2026